Firmware Development for a Sensorized Pleurobot

Enhancing the Pleurobot's capabilities with real-time control, ROS2 integration, and advanced communication systems.

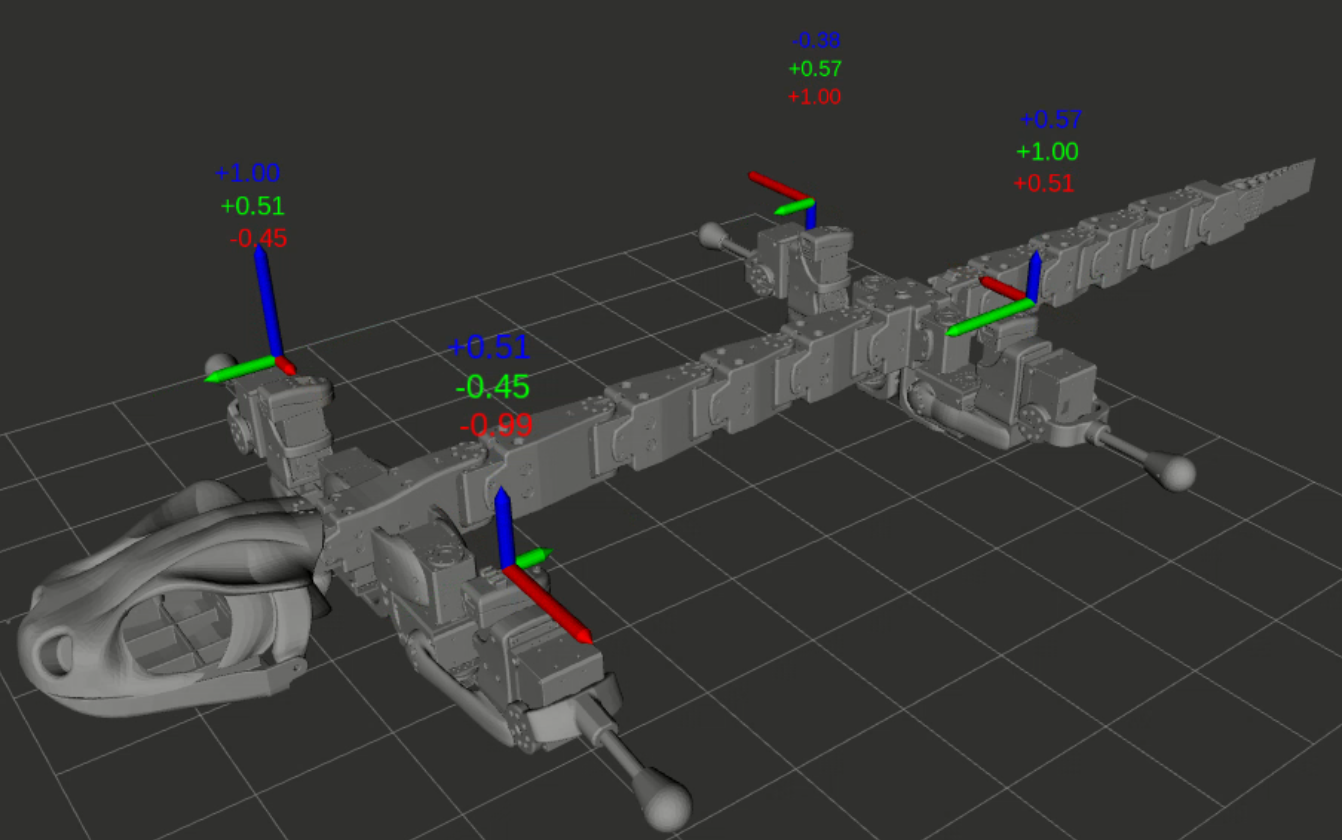

This project focuses on developing firmware and communication systems for the sensorized Pleurobot, a bio-inspired robot mimicking the locomotion of the salamander Pleurodeles waltl. The project was conducted at BIOROB - EPFL, under the supervision of Prof. Auke Jan Ijspeert and Dr. Qiyuan Fu.

You can find the pdf version of the report for this project here.

Objectives

- Sensor Modules: Optimize sampling speed, robustness and communication of sensor modules to the onboard computer.

- Wireless Control: Enable remote operation via a user-friendly interface.

- Integrate Visualization Tools: Develop real-time monitoring using ROS2 and RViz.

Sensor modules

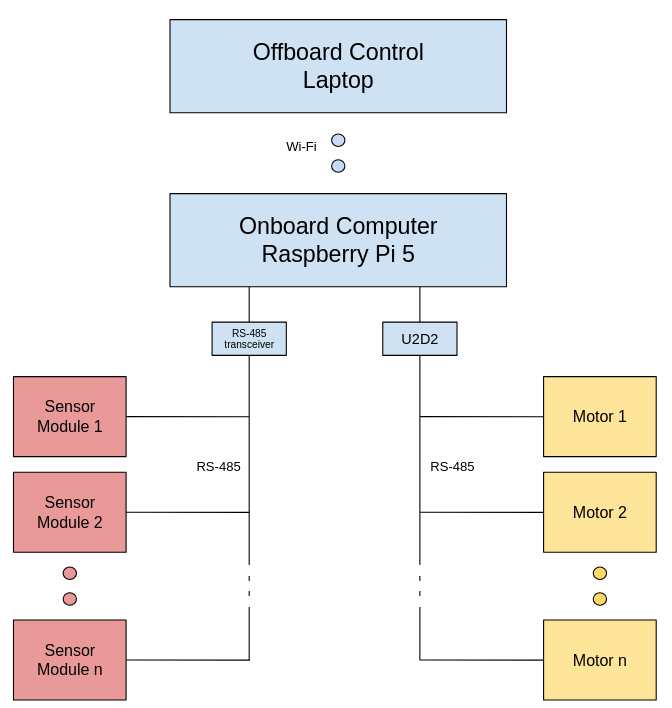

- Original System: Relied on a centralized bus controller for communication, leading to latency and bottlenecks. The bus controller was connected to sensor modules (Raspberry Pi Pico) via RS485.

- Redesigned Communication system and protocol: Eliminated the bus controller by directly connecting the Raspberry Pi 5 with sensor modules (Raspberry Pi Pico).

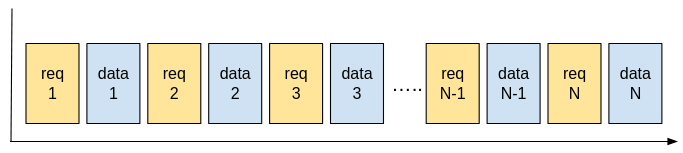

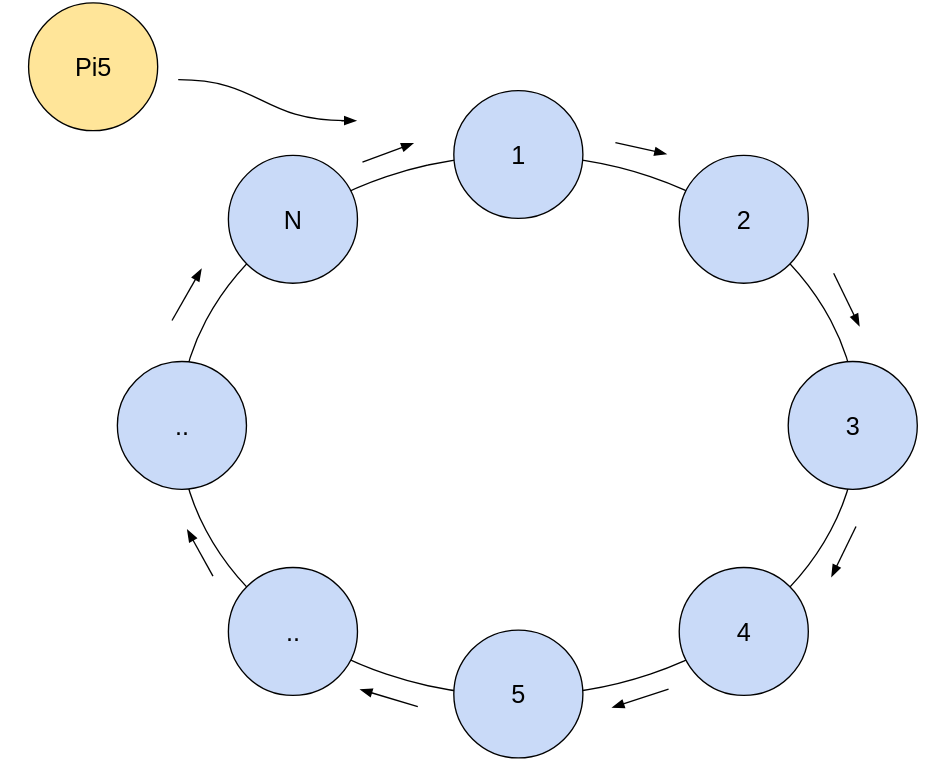

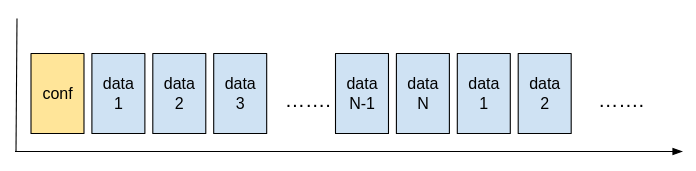

- Custom Protocol: Developed a custom communication protocol for real-time data transmission and synchronization. The custom protocol is based on a token-ring communication, where each sensor module sends data in a round-robin fashion.

This approach allowed for faster communication and reduced latency, enabling real-time control and monitoring.

The latency was reduced from 26 ms to 3 ms, assuming 20 sensor modules on the same bus.

ROS2 Integration

The software stack was integrated into the ROS2 ecosystem, enabling modularity, scalability, and real-time visualization.

- Packages: Custom ROS2 packages for managing robot control, sensor communication, and visualization.

- Visualization: Leveraged RViz for real-time monitoring of force data and sensor states.

- Launch Files: Simplified system startup and configuration.

Demonstrations

- Transparent Force Reproduction

- Data from the front-right leg’s force sensors was filtered and mapped to reproduce forces on the hind-right leg in real time.

- Showcased proportional control and smooth feedback.

- Safe Movement with Force Threshold

- Implemented a safety mechanism that stops movement if excessive force is detected.

- Used hysteresis to prevent frequent interruptions.

Results and Future Work

- Results:

- Achieved very low-latency and high sampling rate communication over RS485 bus.

- Successfully integrated the Pleurobot into the ROS2 ecosystem.

- Organization of development environment and codebase using Git and Docker.

- Future Improvements:

- Develop a custom PCB for the Raspberry Pi 5 for cleaner hardware integration.

- Enhance visualization integrating the complete URDF kinematic model.

- Explore advanced microcontroller options (e.g., RP2350, ESP32) for improved performance.

- Integrate the sensor modules (3-layer PCB) into a single board for compactness and reliability.

Acknowledgments

Special thanks to Prof. Auke Jan Ijspeert, Dr. Qiyuan Fu, and the BIOROB Lab team at EPFL for their guidance and support throughout this project.